Revolving Excellence: The Influence of Trommel Screens in Material Arranging

Revolving Excellence: The Influence of Trommel Screens in Material Arranging

Blog Article

Optimize Recycling Outcome With Trommel Screens: a Comprehensive Overview

As we strive to optimize the reusing output, one tool that has actually acquired considerable interest is the trommel screen. We will check out the aspects that need to be thought about when picking a trommel screen and dive into strategies that can be employed to maximize recycling output.

The Significance of Trommel Screens

Trommel screens play a crucial role in numerous sectors due to their ability to successfully separate and categorize different materials. These makers are created to sift and turn through a range of materials, such as soil, compost, crushed rock, and sand, successfully separating them based on dimension and thickness. This capacity to separate materials is of utmost importance in industries such as mining, building, waste administration, and recycling.

Among the essential reasons that trommel screens are so essential is their contribution to throw away reduction and reusing initiatives. By efficiently dividing products, these screens enable the recuperation and reuse of beneficial sources from waste streams. In reusing centers, trommel displays are typically made use of to arrange various sorts of recyclable materials, such as plastics, metals, and paper, making sure that each product is appropriately categorized and processed for further usage.

Furthermore, trommel screens also play an important function in the mining industry. They are used to divide valuable minerals from waste products, boosting general performance and minimizing the environmental effect of mining procedures. By dividing the materials based upon dimension and density, trommel displays help to make the most of the removal of beneficial minerals while decreasing the amount of waste that requires to be taken care of.

Just How Trommel Screens Job

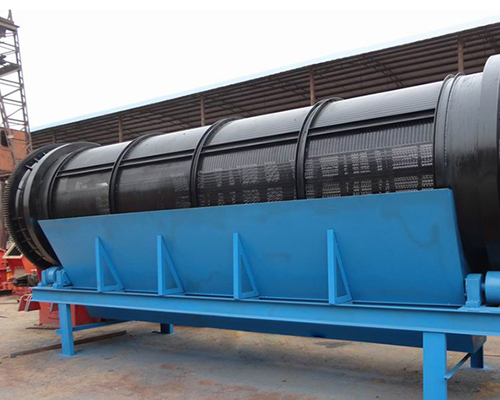

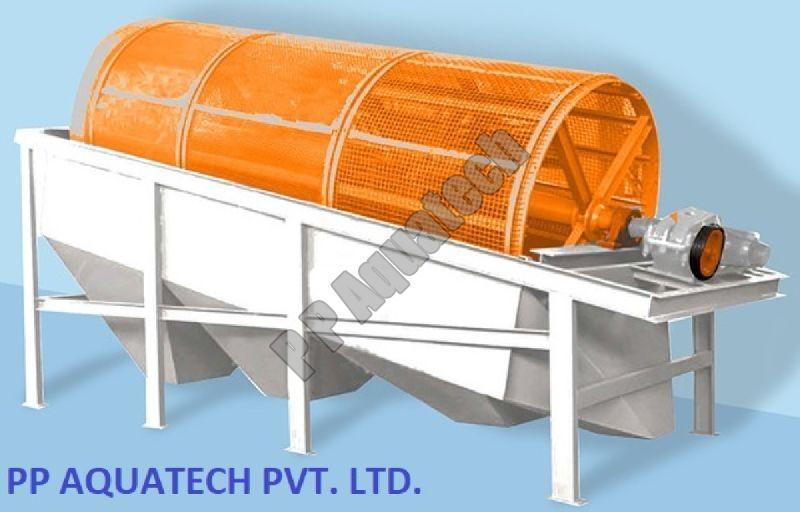

Trommel displays operate by turning and sifting via numerous products to properly different and classify them based upon size and thickness. These screens include a round drum that is slanted on its axis - trommel screen. The drum is usually made of mesh or perforated plates, enabling the product to pass through while maintaining larger fragments

As the drum turns, the product is fed into the leading end. The larger bits are kept inside the drum, while the smaller sized bits go through the mesh or openings. The rotation of the drum aids to lift and topple the product, aiding in the splitting up process.

The rate of turning and the disposition of the drum can be gotten used to regulate the sieving process. By transforming these criteria, operators can enhance the splitting up of various materials. For instance, much heavier materials will settle at the end of the drum because of gravity, while lighter materials will certainly be reached the top and discharged.

Secret Advantages of Utilizing Trommel Displays

One of the considerable advantages of using trommel displays is their capacity to effectively separate and categorize a broad range of materials based on size and density. Trommel screens are designed with turning cylindrical drums that have perforated plates you could look here or screens.

Another benefit of trommel screens is their flexibility. They can Look At This manage a large array of products, including accumulations, compost, metropolitan solid waste, and also contaminated dirt. trommel screen. This adaptability makes trommel screens an important device for different sectors, permitting them to process different types of products with ease

Variables to Think About When Picking a Trommel Screen

When choosing a trommel display, it is necessary to meticulously think about various variables to guarantee optimum efficiency and suitability for details application requirements. One of the initial elements to consider is the dimension and ability of the trommel screen. The dimension must be appropriate for the quantity of product to be processed, while the capability ought to match the wanted outcome. Furthermore, the style and building of the trommel display need to be evaluated. It ought to be able and durable to endure the demands of the application, such as the sort of material being refined and the environmental conditions it will undergo. The screen dimension and setup are also crucial elements to consider. The dimension of the openings or fit together in the display needs to be selected based on the size of the product to be sorted. Furthermore, the display arrangement, such as the number of sections and disposition angle, can influence the effectiveness and effectiveness of the trommel screen. Other important considerations include the source of power, convenience of maintenance, and any added attributes or customization alternatives that may be required for details applications. On the whole, by very carefully taking into consideration these aspects, one can pick a trommel display that optimizes recycling result and satisfies the details needs of their operation.

Strategies to Take Full Advantage Of Reusing Result With Trommel Displays

To maximize reusing output with trommel screens, it is important to execute strategic approaches that profit from the display's capabilities and make best use of efficiency. One technique is to properly size the trommel display based upon the details recycling application. Choosing the right display dimension makes sure that the products are properly separated and permits a greater throughput. Additionally, it is necessary to frequently keep the trommel and check display to make sure optimal performance. This includes cleaning up the display panels to avoid obstructing and replacing damaged components to prevent downtime. An additional technique is to adjust the trommel screen's inclination angle. By discovering the ideal angle, the display's efficiency can be optimized, leading to enhanced separation and boosted recycling output. Using a mix of different screen dimensions or adding added screening stages can enhance the testing process and enhance the purity of the recycled products. Finally, integrating advanced modern technologies, such as automated arranging systems or optical sorting devices, have a peek at this site can additionally optimize recycling result by fine-tuning the separation process and increasing the recuperation rate of beneficial materials. By implementing these calculated methods, reusing facilities can optimize their result and add to a much more lasting future.

Conclusion

By considering essential variables such as screen capacity, size, and upkeep demands, one can select the most appropriate trommel display for their recycling operations - trommel screen. Applying strategies like appropriate material prep work and routine maintenance can further boost the performance and productivity of trommel displays, inevitably leading to a higher recycling result.

In reusing centers, trommel screens are generally utilized to sort various types of recyclable materials, such as plastics, steels, and paper, guaranteeing that each product is effectively classified and refined for additional usage.

Trommel displays are developed with rotating round drums that have perforated plates or screens. The screen arrangement, such as the number of sections and inclination angle, can impact the performance and efficiency of the trommel display.To optimize recycling outcome with trommel screens, it is vital to execute critical approaches that take advantage of on the screen's capabilities and make the most of performance. By considering key factors such as screen size, capability, and maintenance needs, one can pick the most appropriate trommel display for their reusing procedures.

Report this page